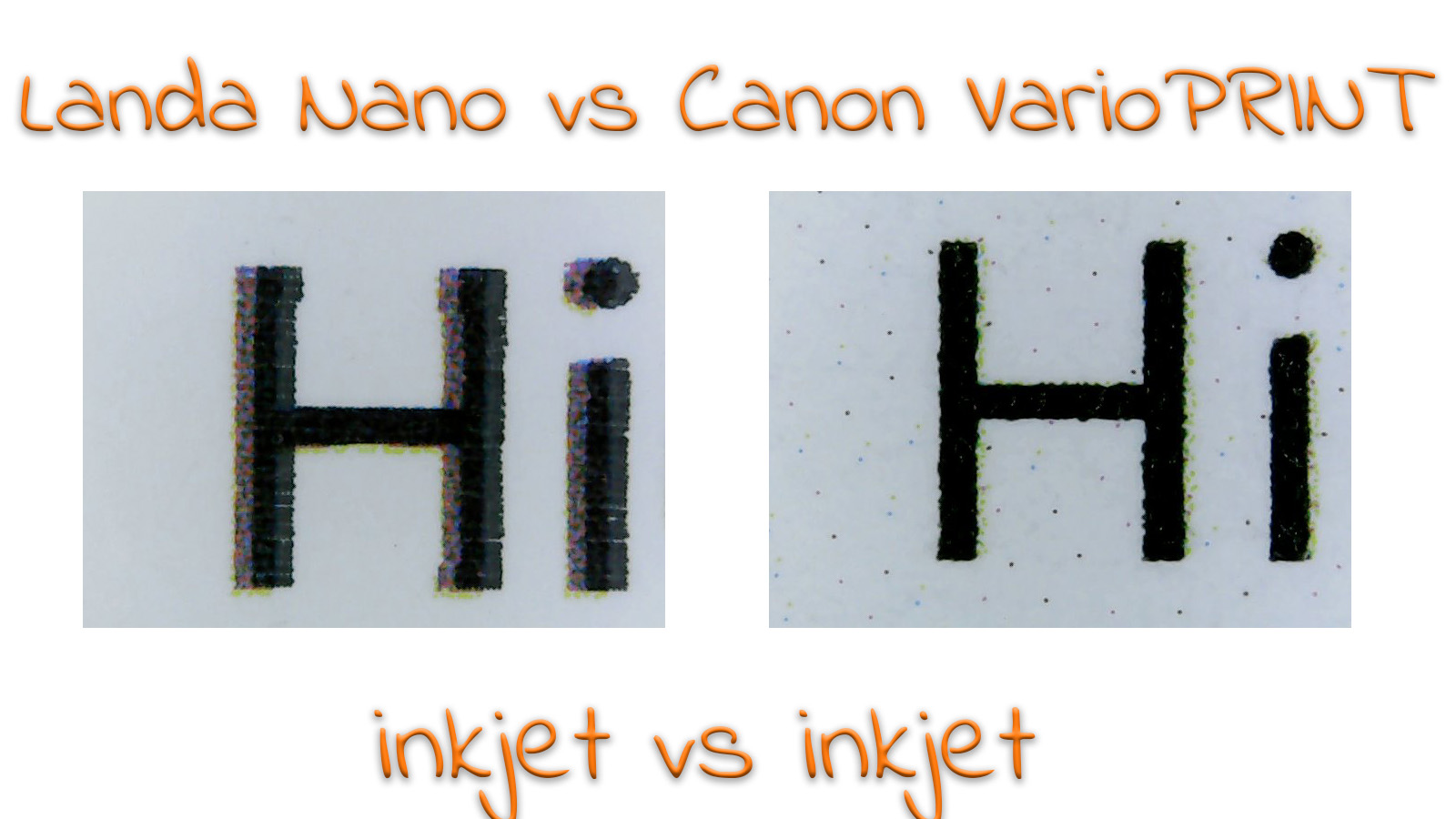

The article about the Landa Nano print quality in real life did gain some traction: within 24 hours, it was read over 1.000 times, it was shared a lot via LinkedIn, via WhatsApp. But one could argue that the comparison with the Xerox Iridesse and HP Indigo 7900 isn’t 100% correct: it was inkjet vs toner and liquid toner. So here is a new comparison, one with another new inkjet press: the Canon VarioPRINT iX.

CONTENTS: Canon VarioPRINT iX | The samples | Does size still matter? | A curious thing | Why is this important?

It took a bit of effort to get these samples. I first asked one of my old contacts in Venlo if I could get some samples. (see full disclosure below) He forwarded the question to his colleagues since he wasn’t involved with this product range anymore. They were certainly interested, but it could take some time: they were printing lots of customer jobs on their demo machine, and these, of course, got priority. Several weeks later, I still didn’t get the samples. So I tried another route: one of my blog readers told me that one of the first VarioPRINT iX presses was recently installed in the Netherlands, at Kampert-Nauta. They even have a nice video on their website of the installation of the press.

After some back and forth, they were happy to provide me some samples printed on their production machine, both on coated and uncoated paper, with the XCMYK profile. I still had to wait a little bit: the machine is already running in 3 shifts, they needed to check the planning when they had a time slot for my prints.

The samples

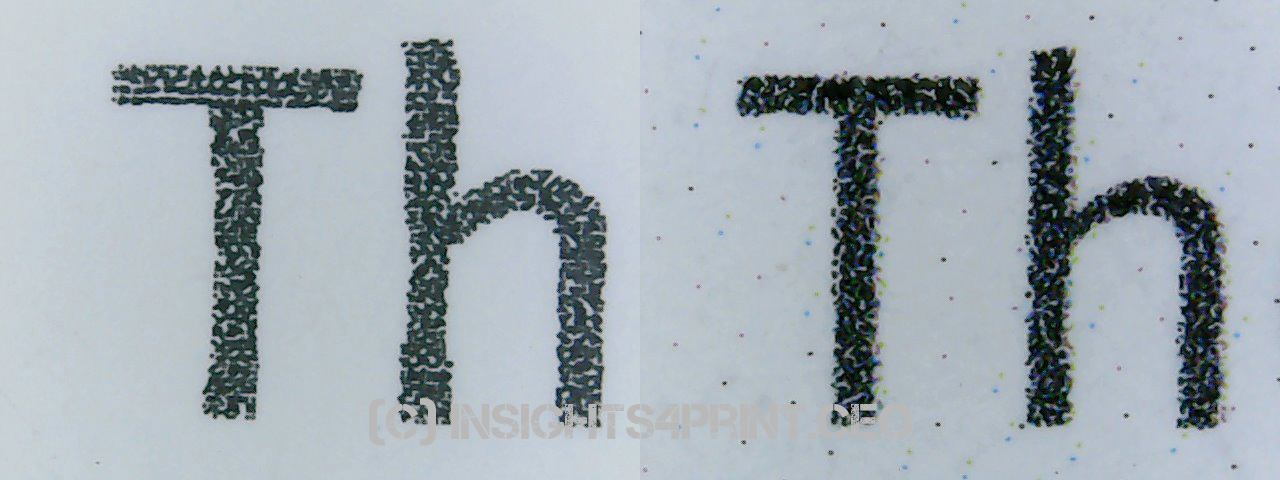

Earlier this week, the samples arrived. And the first impression was that the print quality looks better than the Landa Nano samples. Registration was certainly better, the screening looked better to me (but that’s a personal impression). And: blue was really blue. Only in the coated sample the darkest blues were slightly going into the purple direction, but that’s probably nitpicking. Plus: I didn’t see any artifacts like banding or failing nozzles. Not in the color images, not in the black/white image, not in the text.

Please click on the images below to enlarge them!

On failing nozzles: when looking at some of the samples above, you may have noticed the small drops in the background. I wondered what these were, and these seem to be ‘refresh dots’, to keep the nozzles open. To be clear: you won’t see them with the naked eye, even with a loupe, they are tiny.

Someone had already mentioned that technique in a comment to my previous article, as a possible explanation for the ‘contaminated’ solids in the Landa Nano samples. But there is a clear difference between the two: the VarioPRINT shows a minimal amount of dots, and the dots are in all process colors. While the Landa Nano samples showed only contamination in the solids, not in the background, the ‘paper white’.

What is interesting: I also got a sample from the web-fed Canon ProStream 1800 recently, also a piezo drop-on-demand inkjet. And that one doesn’t show the refresh dots. Maybe it’s the difference in speed that eliminates the need for refresh dots (up to 133 m/min for the ProStream vs 9000 SRA3 sheets for the VarioPRINT ix)?

Added 23/11/2020: the ProStream seems to use a ‘refresh bar’.

Added 20/03/2022: it seems the refresh dots can also be configured to be a refresh line, printed outside the print image / trim box. Book printers seem to prefer that configuration, commercial printers don’t seem to mind the refresh dots as shown in these samples.

Does size still matter?

There is one thing where the Landa Nano is quite different from the Canon VarioPRINT iX and also the Xerox Iridesse and HP Indigo 7900 from the previous article: sheet size. The Landa Nano S10P is a B1 sized press (75 x 105 cm), the others are smaller. And the larger the format, the bigger the challenges, especially registration.

- Landa Nano S10P: 75 x 105 cm

- Canon VarioPRINT iX: 35 x 50,8 cm

- Xerox Iridesse: 33 cm x 48,8 cm (it also has an extra-long option)

- HP Indigo 7900: 33 x 48,2 cm

A larger sheet size really mattered in the old days: with large runs, you could save on paper waste, and for a long time, finishing equipment was geared towards larger formats. But with shorter and shorter run lengths these days, e.g. a few hundred, and new types of finishing equipment geared towards these smaller sheet sizes, does that larger size still have advantages? It’s a sincere question, not an opinion. So, if you can shed light on that, please leave a comment! I would really appreciate your insights on this!

A curious thing

There still is something curious, something I still don’t know what to make of it… The previous article did go around the printing industry quite fast. According to Google Analytics, it was shared on LinkedIn and WhatsApp, it’s mentioned in Disqus threads. In the days following the publication, my LinkedIn profile was checked by dozens and dozens of people. Including people working at Landa Nano. So the company is aware of my article, for sure.

And that’s what is curious: they know about this not quite positive, even hype-busting article, but they didn’t respond to it. Not in the comment section, not via a direct channel. They also didn’t provide a better sample, although the printer promised one. And if I would have gotten one, I would have included it in the previous article, I clearly stated that.

If I were someone with even just a little bit of responsibility in a company that is launching new technology and reading such a review, I would immediately act on it and get (someone) in contact with the reviewer. To check what might have gone wrong and to deliver a better sample. But Landa Nano chooses not to. They choose to neglect me. Which, of course, is their good right. And, let’s be honest: who am I in the printing universe? What does this blog represent?

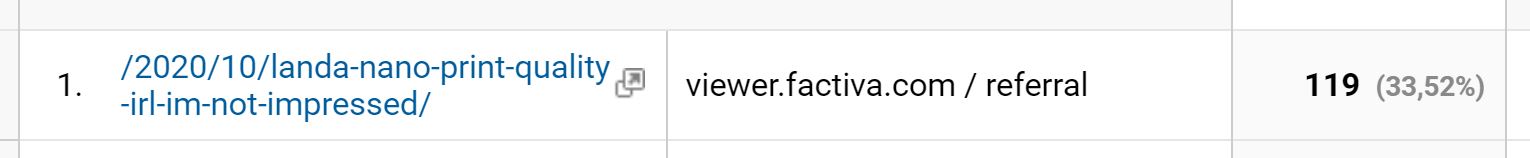

But I have to share with you something peculiar: a referrer I discovered in the analytics… Two weeks ago, there was a brief spike in the number of visitors to that article. The referrer was something I never heard of, viewer.factiva.com.

So I tried that URL in my browser, and there was a surprise: it’s the Dow Jones newsletter! Why would they put a link to my article in their newsletter? Is Landa Nano looking for new investors?

Update 20/02/2021: the Factiva-mystery has been solved. Another digital press vendor used this newsletter service to inform its employees about that article…

Why is this important?

When looking to invest in new production equipment, always check what is on the market and check this with your own files, with customer files. Don’t rely on hypes and prophets. Trust only your own eyes, your own people. Only then can you make a good decision.

Landa Nano has been promising heaven and beyond, for eight years already. A claim that isn’t substantiated in the samples I got. As I have shown above and in the previous article, there are many more and better options out there if you are looking for a production press.

Full disclosure: in the early days of developing what became the Varioprint series, Océ Venlo hired me to educate the R&D team and the ‘business unit’ on the printing industry and the requirements for commercial printing. I have done that training many times, the last session is at least over 5 years ago. Since then I do not have any commercial links to Océ / Canon anymore.

PS: the counter below is wrong, the website crashed due to a bad plugin update on 22/11/2020. Restoring the backup deleted about 175 visits that day.

UPDATE 29/08/2021: Interesting news this week: Cimpress announced that it is investing in Canon inkjet solutions. Why this is perticularly interesting: in 2016 there was an announcement that Cimpress was partnering with Landa Nano: “Cimpress intends to purchase up to 20 presses upon completion of successful testing (…)”. As far as I know, no Landa Nano press was (officially) installed at a Cimpress company. So I assume the tests were unsuccessful.

UPDATE 12/04/2022: check out this closer look at the ‘world record’ for the Landa S10P!

UPDATE 31/05/2024: as a reference, in a drupa video, Canon stated they have over 600 installations of the i(X)-series machines.

UPDATE 08/06/2024: I took home over a dozen samples from Landa Nano from drupa 2024. Here’s my review (and it doesn’t look that good): Landa Nano, The Good, The Bad, The Ugly.

Interesting. Understandably I am only interested to know if the Landa presses are capable of printing in accordance and to similar visual standards as offset CMYK ISO 12647-2-2013 – Fogra 51 and Fogra 52 and perhaps to to immitate offset printing to the older standard – Fogra 39 and Fogra 47. It would be interesting to see a visual comparison between 4 colour offset presses and the Landa – since Landa aims to replace offset presses. I understand where you come from Eddy as a photographer and of course you want the sky to be blue, not purple but to pull that off properly you need extended gamut. I always thought the Landa presses were just 4 colour – CMYK.

Hi Ingi!

Be careful what you state: I have been promoting standardized printing (ISO 12647-2) in the Benelux long before it became fashionable. 😉 So I’m all for standardization.

And using that standard wouldn’t prohibit you from converting blue in RGB to a blue (although less saturated) in CMYK… Only on the existing profiles do an awful job. And it might not be the gamut that’s the problem. Just try this: take a nice blue picture and convert it in Adobe Photoshop with US Newspaper (SNAP 2007), it’s a profile that is included by default. It’s newspaper printing, so a pretty small gamut, but blue stays blue, no shift towards purple…

Landa Nano claimed a large color gamut from the start. However: that might be limited to their 7-color presses. At least a number of the installed presses have the 7 printing stations, but only 4 are active at this moment. I don’t know why. Landa Nano said that the 3 extra colors would become available in the near future in their communication. What the ‘near future’ is, of course, depends on your perspective…

Comparing Landa Nano with offset: well… interesting story here… My friends at DeGrafischeVakpers.nl (the Graphic Trade Press) were invited, together with some others, by the first Landa Nano customer in the Netherlands. The printing company showed the same test file printed on the Landa Nano, a Komori offset press and an HP Indigo. They could look at them in the press room (please note: they were printed in advance, not in real-time). And they could even take a set of samples home. But there a ‘mistake’ happened: back home, they noticed that only Landa Nano samples were included, the offset printed samples were missing… Another of my readers has asked another media outlet that reported on that event and declared the different prints were all the same, to get measurement data, verifying that claim. No response.

The web fed Canon inkjet uses a refresh bar. They fire all the jets at end of the page, this can be trimmed out with a double cut on the finishing equipment.

Aha, thanks Carl!

Hi Eddy

I believe in the Canon DFE the the ‘feature’ of the small nozzle clearing dots on white areas can be switched on or off as needed.

The issue of RGB blues turning to purple in CMYK has been a probable since Fogra 27 based profiles. I have found in practice the using eciRGB rather then AdobeRGB and Fogra 39 and 51 profiles made using the latest colour management softwares does minimise this issue.

Interesting Paul! I’ll check that.

I just tested it: exported the image of the Grand Place from the RAW file to eciRGB_v2_ICCv4.icc, converted that with PSO coated v3 in Adobe Photoshop, but I don’t see a difference with the route via AdobeRGB… The blue skyes are still purple. 🙁