If there is one printing company that excels at using social media, it’s Reclameland.nl (Simian). Wouter (the owner and literary the ‘face’ of the company) does an excellent job! And I mean that. And his most recent achievement is the ‘Landa World Record’. I assume he did break the record (it’s a small category, after all, and Benny Landa himself said Wouter set a record). But when looking a bit closer at the numbers, I’m not sure why they are celebrating this…

CONTENTS: The setting | The numbers | The discrepancy | Champagne! | Why is this important? | Updates

The setting

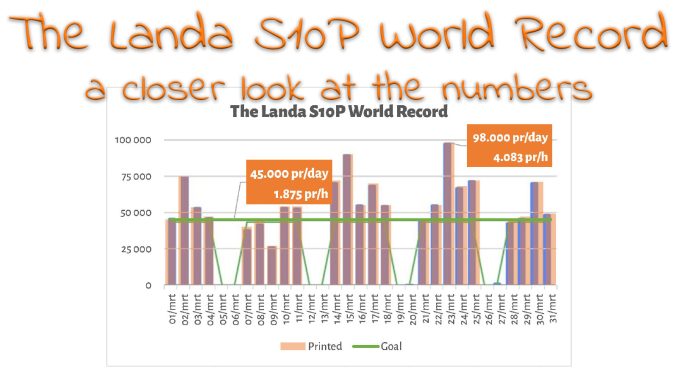

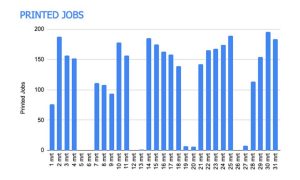

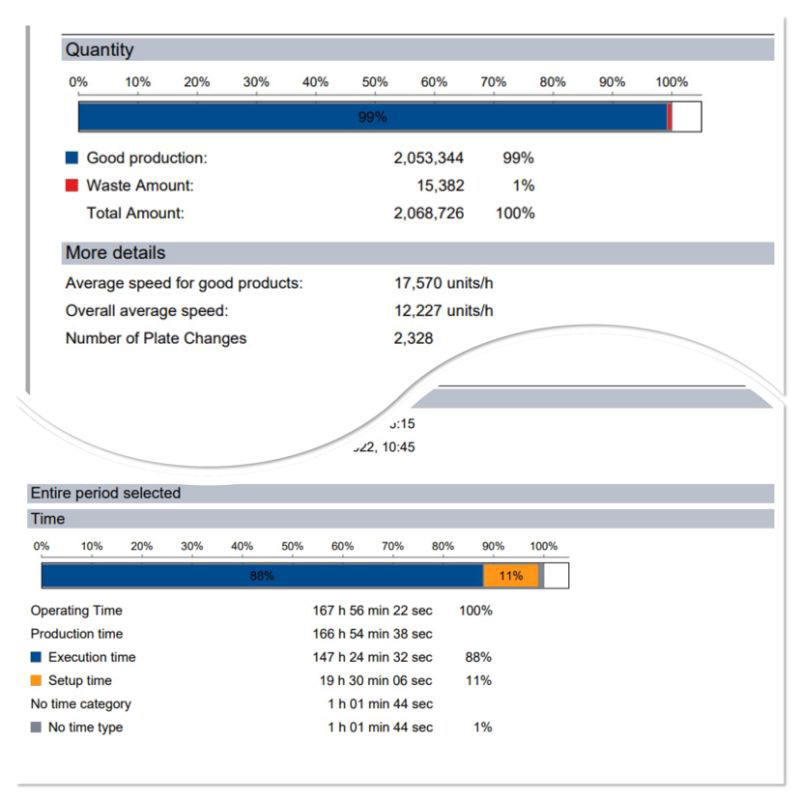

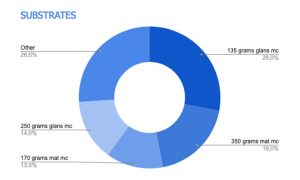

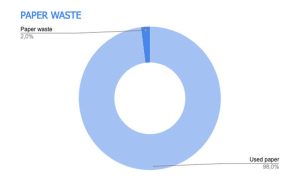

First, let’s look at the setting. Reclameland.nl has a Landa S10P, which is the ‘perfecting’ sheetfed version (so it prints on both sides of the sheet). The test was to print as many sheets as possible in one month, when operating 24 hours per day. The orders, over 10.000 customer jobs, were on multiple substrates, with varying run lengths. The graphs below show more information, these were published on this page.

The numbers

The website only shows a graph, next to the total amount of sheets printed in March 2022 (1,33 million). To get a better idea of the daily production, I recreated the graph in Excel (if you want to know how: I put the original graph in the background of a graph linked to a table with data, I tweaked the data so that the size of the bars was equal to the original, in the graph below the orange color are my numbers, this is partly transparent, the blue in the background is the original graph). And the total I get for the entire month, is quite consistent with the total Reclameland.nl mentions: 1,33 million vs 1,3 million sheets.

What interested me the most was the goal they set, the average and the most productive day. That’s what you want to know, isn’t it?

The goal seems to be set on 45.000 sheets prints in 24 hours. Which means: 1.875 sheets prints per hour (45.000 divided by 24). And this is something I’m not really getting: the advertised speed of the Landa S10P is 6.500 sheets (or better: prints) per hour… That’s also the speed Wouter mentions in his video. So why did they set the goal so low? Doesn’t the press run at de advertised speeds? Or is there a lot of unproductive time? The goal wasn’t even one third of the theoretical throughput… Why? I really wonder why?

For the average in the table below, I left out the second week, since one of their operators had an issue and couldn’t work.

| prints/hour | compared to 6.500 pr/h | |

| Goal | 1.875 | 29% |

| Average | 2.573 | 40% |

| Max | 4.083 | 63% |

Now, there might be a little confusion about the speed: is it sheets or prints per hour? Being a perfecting press, you have 2 prints on 1 sheet. And this shows in the specifications of the Landa S10P press: single sided the speed is 6.500 sheets/hour, double sided (perfecting) it’s 3.250 sheets/hour. Which is still 6.500 prints/hour, but one on both front and back, therefor 3.250 sheets/hour. And the speed mentioned in all communications about this world record is the 6.500 prints/hour.

The discrepancy

Where does the difference between the official specifications and this real-life test come from?

My two guesses:

Maintenance: how much maintenance is needed? The belt has been a problem in the past, although it should have improved recently, according to this article. (*)

Substrate changes: the Landa press has a design similar to offset presses, meaning: one paper feeding spot, where you can place a pallet with paper. For large orders, or if you mostly print on one, or a limited number of substrates, that’s a good idea. But when substrate flexibility is key, in combination with small order sizes, it is not a good design, IMO. The setup of other digital presses, which have smaller maximum sheet sizes, seems to be a better fit for this combination: multiple input trays, where you can place multiple substrates and even change and full these while printing. What could also make job changes time-consuming, is if the press needs ‘adjustments’ (automatic or not) when a different substrate type is loaded. If you’re interested in digital presses, do check this out! And also, the amount of maintenance that is needed.

If you have other guesses, please leave a comment!

Since I mentioned the sheet size, that’s what’s unique about the Landa S10P: it’s B1, it is the only digital press with this sheet size. In a previous post, I already discussed this and asked whether this has any benefits over the smaller sizes of most digital presses, given the current technology and markets. But nobody shared his/her insights.

(added 12/05/2022: to be clear, I’m not questioning B1 format presses in general, I’m questioning B1 in digital presses; for offset it certainly makes sense)

In the old days (when I was young), a large sheet size did matter, with finishing equipment as one of the critical factors. But these days, we do have decent finishing equipment for smaller sizes. And run lengths have come down significantly, so repeating the same order to fill a large sheet doesn’t make any sense anymore. So, I still wonder where the large sheet size benefits (with the exception of large prints like posters). If you have an idea: please leave a comment! I really would love to know!

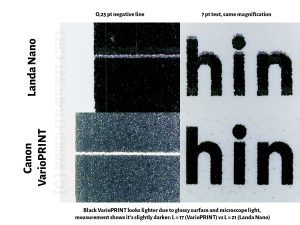

And this sheet size could be an important, even fundamental issue: with a bigger sheet size, faults become more prominent. And the Landa S10P has an issue there: even in recent samples, I saw a registration issue.

Champagne!

The video where Wouter shares the results of his one-month test, includes several interventions by Benny Landa himself. He is really proud of the achievements of Reclameland.nl, almost ecstatic. The main reason: Reclameland.nl is the first Landa S10P customer that has broken the 1 million impressions per month mark!

But wait… Is that something to be happy about? A reason to open a bottle of champagne? With a dozen or two installations, many already active for 2 years or more, it is the first time someone reaches the 1 million impressions per month mark. What does that tell us? Is Reclameland.nl the only one running it in 3 shifts? Well, that might be the case, as Wouter claims in one of his vlogs that he is printing 24 hours a day and that hasn’t been done before on a Landa press.

Which seems a bit strange to me, as one of the ‘Key Benefits’ of the Landa S10P is the “printing at offset speed and quality”.

If I would have bought a ‘production machine’ that claims 6.500 sheets/h, with promises of even doubling that speed, I would probably use that bottle of champagne to get drunk and try to forget this world record…

Why is this important?

There are two important lessons from this test. The first is the power of social media and what it could mean for printing: Reclameland.nl succeeds in drawing attention to print, making print exciting! And that’s what we need! Printing is an innovative, technological industry. And we need bright young people, very hard. The coming decade we will see a lot of retirements, and many vacancies need to be filled. So, kudos to Reclameland.nl to use these modern communication channels to promote their own company and print.

The other important lesson is the discrepancy between marketing promises and real life. When looking at the specifications, the Landa machine looks amazing, it even demonstrated 13.000 sheets per hour!!! With zero change-over time between jobs, that should be a production beast.

But the numbers from this real-life test show something different… The expectations set by Reclameland.nl were low (45.000 prints in 24 hours, 1.875 prints/hour). Why? Only to be sure they would reach and exceed the goal? And when comparing the actual prints to the specifications, there is a big gap between the theoretical possibilities and the ‘world record’. Why? Does it not work at the promised speeds? Do job changes require much more time (especially when other, more difficult substrates are used)? Is maintenance an issue? Is that very time-consuming? Or all of the above? I’m curious…

So, if you are looking for a new digital press, digital printer, here’s some advice: check with a colleague who owns one to see what it is in real life, what the productivity level is, e.g. the average speed, the uptime or even the OEE. Check how much maintenance is needed, how substrate changes are handled. And order a print job there, that’s the only way to see the real-world print quality. It will cost you a few euros or dollars, but it might save you a lot of money afterward…

(*) there is also another interesting statement in the article: “Meier expects the machine to run with absolute stability from this summer, as he is used to from sophisticated offset printing technologies.” Which seems to indicate stability might still be an issue and needs to be fixed, or at least that it’s not at the level of offset printing yet.

(The original text in German: “Meier rechnet damit, dass die Maschine ab diesem Sommer absolut stabil laufen wird, wie er das auch von ausgereiften Offsetdrucktechnologien gewohnt ist.”)

UPDATE 11/05/2022: one of my readers just send me a link to another world record. A KBA Rapida 106 (about the same sheet size as the Landa S10P) printed 444.444 sheets, in 24 hours… That puts the 1 million prints a month from Landa in perspective. Off course, the KBA Rapida is an offset press, and the article doesn’t mention average run size.

UPDATE 23/06/2022: to put the numbers above in perspective, in a LinkedIn-post Anthony Thirlby shared the following numbers, which represent one week production on his Heidelberg Speedmaster XL 75 5-color. In the post he also mentions: 1 min 43 sec makeready, 23 sheets makeready, substrate range: 90 gsm > 400 gsm, average run: 3.200. And capacity per year: 104 million impressions.

UPDATE 16/11/2023: Here’s an important update! Last week the first Landa presses reached 20 million flats. But guess what: it was NOT the press at Simian, it was another one. And even one that was installed after the one at Simian… So couldn’t they keep the productivity of that ‘world record’? Or are there other reasons? Simian did declare they were moving jobs from their Komori press to the Landa press, but in that case: shouldn’t they have reached that 20 million flats first? Here’s my look at the new Landa celebration.

So, thats 6500 sheets per hout one sided, 3250 per hour perfected. So allowing for a generous 1/2 hour change for each job and a net 85% production speed for issues such as paper loading etc would give:

Based on 6 ‘job’ changes per 8 hour shift equals 5 hours press running time and at 85% of maximum speed equals 27,000 impressions per shift, 81,000 per 24 hours, then based on a 28 day month, 2.2m impression. So something is odd!

Thanks for your comment Paul!

There is certainly something odd… these are not numbers you would expect from a ‘production press’, from a product you have to pay a lot of money for…

Heidelberg and Fort Dearborn did a press release recently on a litho offset press world record which is interesting to compare with Landa digital.

“In addition to achieving nearly 82 million impressions last year, Fort Dearborn reached an Overall Equipment Effectiveness (OEE) of 53.85% on its XL 106 — compared to the industry average of 25%.”

I think many in the industry believe printing is normal manufacturing and OEE in the 80’s% is achieved all the time. When the data is actually measured (most do not actually collect data) I have rarely encountered over 50% OEE in my 25 years in printing.

https://news.heidelbergusa.com/2021/04/fort-dearborn-sets-world-impression-record-on-heidelberg-speedmaster-xl-106-in-2020/

Thanks for sharing this Martin!

I’ve seen numbers (graphs) of Heidelberg users in the past, on LinkedIn, but forgot to save them…

I didn’t know they about this press release.

Hi Eddy,

good insight as always. On the “why B1” question:

From my time in offset press manufacturing going from B2 to B1 essentially meant doubling capacity. Presses run essentially the same speed in sheets/hour, but a B1 sheet is twice the size. Same is true for web-fed.

There are some side benefits:

– 1 B1 requires less staff than 2 B2 presses

– A B1 press is less expensive than a 2 B2 presses

– Materials are slightly cheaper

Rarely is the larger format needed as such in commercial print (posters, imposition of odd formats,…)

In digital print all this might be somewhat less important as short runs, inline finish, multiple paper trays, automation,… have their own dynamics.

Still a B1 digital press is a great option for the market

Thanks Ralph!

And certainly thanks for your insights on the “why B1” questions.

In the offset print world of two decades ago, I can perfectly understand the benefits of the larger format. But with print jobs these days, I still find it a difficult question. With different substrates and different run lenghts, it looks hard to me to efficiently combine jobs on a B1 press. Unless you have either a large customer base and a large number of print jobs; or unless your lead times are longer.

There are still many reasons that many printers need B1 presses:

A4 16pp sections for binding multi page work

6pp and 8pp ‘gate folded’ covers and inserts

Over sized ‘B4’ page production on B1 sheets

Better ganging options, especially in the packaging market

Plus all of what Ralf said above and others that I am sure I have missed.

Hi Paul, just to be clear: I’m not questioning B1 presses in general, only for digital. In offset it certainly makes sense.