The word is a kind of magic, mystical: the ‘crossover’ between digital and offset printing. It’s the holy grail. It’s the number everyone wants to know. It’s a number that some vendors are showing off with. Landa Nano, e.g., has a bold claim it’s 5000 sheets. But numbers can be very different, and you have to use the correct number when investing in new equipment. Let’s dig in deeper! And, spoiler alert: based on actual prices of online printshops offering the choice between digital and offset, it’s between 150 and 250 sheets. And a recent article, about the latest investment of an online printer, even claimed 50 sheets to be viable in offset… That’s a factor 100 different from the 5000 sheets claim… Let’s check this!

CONTENTS: The magical graph | Crossover in real life | Complicated, and fluid in time… | Job change sheetfed offset press: 2 min, 13 seconds | Why is this important?

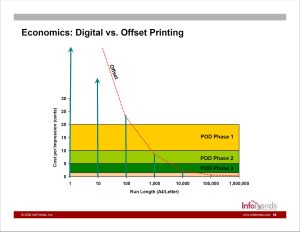

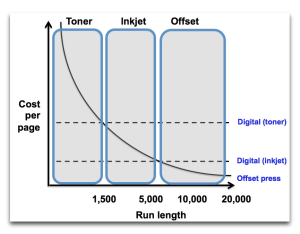

But first, a bit of background. There once used to be On Demand, a conference and show about the then emerging digital print world. In the early 2000s, I attended it numerous times. And during the keynotes, the people from CAP Ventures (which later became InfoTrends and now Keypoint Intelligence) showed a magical graph: the crossover between digital and offset. With several lines for digital: the different phases.

At first, this looked very credible to me. CAP Ventures were the experts studying digital, I had no reason to doubt their findings. But over the years, while digital entered new phases, offset stayed the same. Even after one, even two drupa shows, when offset demonstrated a big step forward in terms of makeready times… I guess I’ve seen that same graph for at least a decade… If I recall correctly, the last time I saw it was at a meeting during drupa 2012. By then, it had become clear to me already for some time: they did study digital continuously, every inch it moved, but not the less sexy advancements in offset… Even though these definitely impacted that (in)famous crossover number.

Some vendors are still using that magical crossover in their promotional material. Until recently, Landa Nano had a claim on their website that the crossover would be around 5000 sheets. (Since Landa Nano redesigned the website in June 2022, some information is no longer available, but fortunately, there is something like The Internet Archive. This archived page shows the claim, this ‘snapshot’ dates from 22 November 2021)

And also, this blog post from 2016 on the Xerox website shows a graph claiming a crossover with inkjet around 5000 sheets.

A 5000 sheets crossover seems on the high side to me. So, I set on a quest to find out more.

Crossover in real life

To get an idea of the crossover in real life, I put the question in the LinkedIn group Print Production Professionals. But to my surprise, only a few comments. (I had hoped that the offset printers in the group wanted to brag about their efficiency.) The one result I got from an offset printer with also (decent) digital equipment, a Xerox Iridesse, was 250 to 300 sheets. Which is much less than the claimed 5000 sheets…

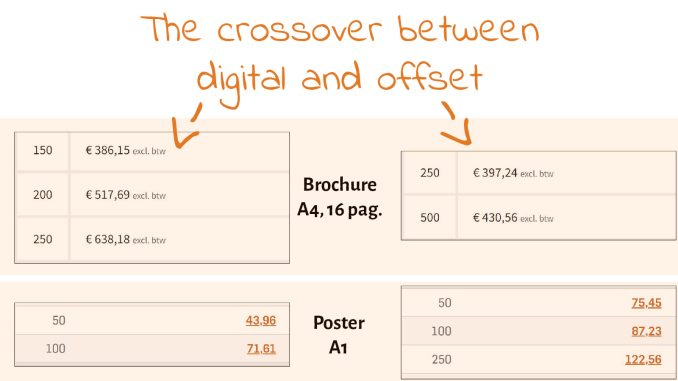

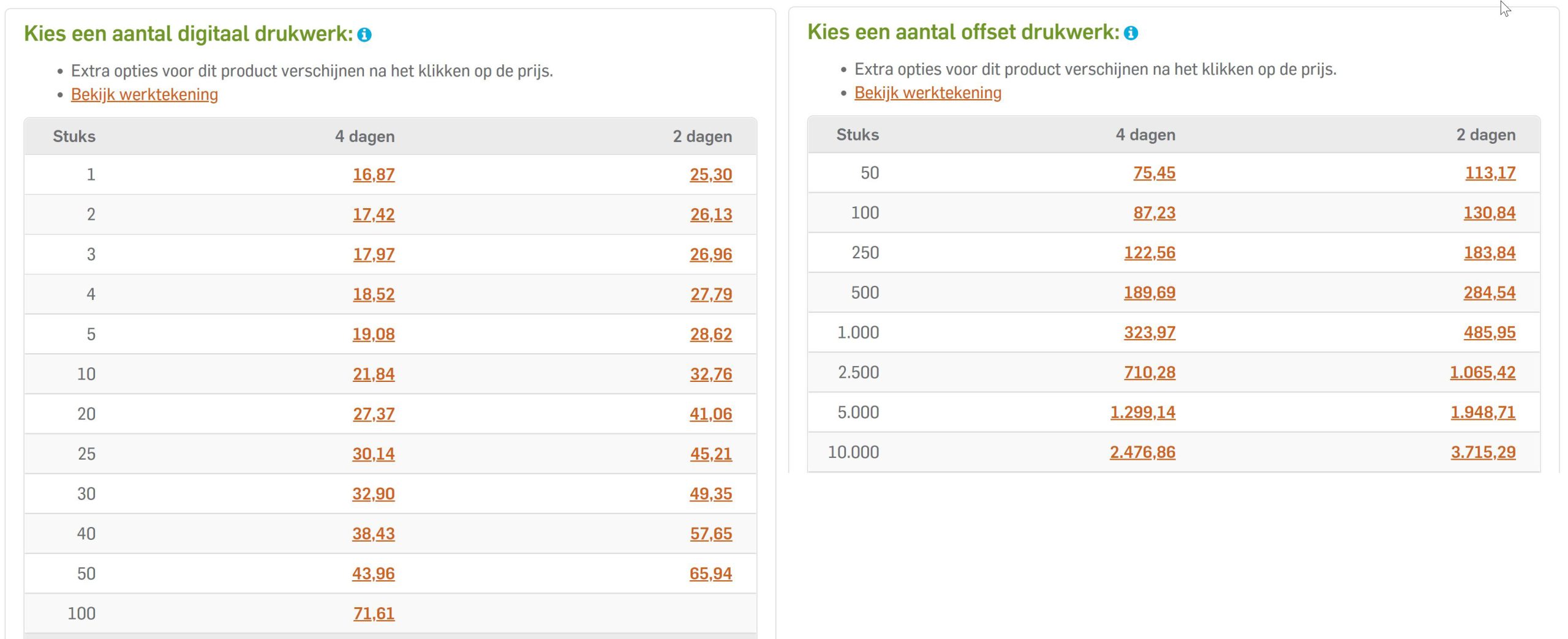

So, not getting sufficient answers in that group, I took another approach. In the Benelux region, where I live, some online printers mention the technology used for a specific order. When you define a type of product, you will see two tables with possible run lengths and the prices. First, a table with the prices for digital, being the lower run lengths, then a table for the higher run lengths, with the prices for offset. Which should give a decent idea about that crossover.

Now, I know that sales prices don’t always reflect the actual cost, there might be more involved. The sales price is a management decision, also driven by ‘the market’. But given the fact that I’m comparing offers in both digital and offset from the same printing company, cost structure (overhead, …) is the same. So, it at least provides an indication in what region of run lengths printers offering both shift from digital to offset.

As an example, I took a job that can perfectly be done in both digital and offset: a brochure, A4, 16 pages, standard paper (135 grams), stitched, self-cover, no special finishing.

Let’s take a look at some prices. I eventually found five online printers effectively showing prices for both digital and offset. In the table below are the website, the maximum run length they offer in digital, and the minimum run length in offset. Plus: for which run length in digital the smallest job in offset is cheaper… The crossover.

(in one case I’ve also included the prices, so you it will become clear, I do have screenshots from all websites with their prices)

| Printshop | Digital up to… | Offset from… | Crossover (offset cheaper than digital) |

| Drukland.nl | 250 | 1000 | <200 copies in digital |

| Flyerzone.nl | 250 | 500 | <250 copies in digital |

| Reclameland.nl | 250 (364,27 €) | 500 (304,48 €) | <250 copies in digital |

| Printdeal.be | 250 | 250 | <250 copies in digital |

| Drukbedrijf.nl | 250 | 250 | <200 copies in digital |

These names might not ring a bell, but there are some things you might want to know… Printdeal.be, e.g., is part of Cimpress (the holding above Vistaprint). And then there are the first three in the table: Drukland.nl, Flyerzone.nl, and Reclameland.nl. These are the three brands from a company named Simian (NL), a company that owns a Landa S10P… Claiming a crossover at 5000 sheets (see above), that is a press that should be a perfect fit for this kind of job. But Simian still sells offset from 250 copies and above. At a price cheaper than 250 copies in digital. Why? BTW: the Landa press was installed about two years ago, so they should have had the time to update their website and pricing mechanisms.

It could, of course, be that the Landa digital is not in the ‘digital’ category (it’s certainly not in a specific category of its own). So, I tried something else on the website of Reclameland.nl: a poster. The website first makes you choose between short (1 – 50) and large (50 – 5.000) run lengths.

When selecting an A1 poster (which fits nicely on a B1 sheet, the maximum size of the Landa S10P) and 170 grams paper, no special finishing, digital is offered up to 100 copies (more than the initial choice up to 50), at 71,61 euro. For offset and 100 copies, that’s 87,23 euro. When putting the two lists of run lengths and prices in Excel, it’s not hard to find the pricing structure for both. And knowing that, I calculated the pricing of more run lengths. Guess what: at 150 copies, the price level is almost equal (0,19 euro difference). From 151 copies, offset is cheaper. And this is with a job that should be a perfect fit for a Landa S10P.

BTW: as you can see, the run lengths offered in the offset table go to 10.000 copies, the pricing structure I found applies to the complete list of run lengths.

Complicated, and fluid in time…

When I posted the question in the LinkedIn group ‘Print Production Professionals’, I immediately got a response from Deborah Corn, the manager of the group: “I have come to accept, after 100’s and 100’s of interviews with OEMs and printers, that the answer to the run length question is more than likely going to be… it depends.”

Now, I wasn’t looking for a number engraved in stone. I intended to start a discussion, with printers sharing THEIR numbers, not the numbers that press manufacturers claim, both digital and offset.

And it indeed depends, absolutely right! And that’s what printers need to know: it really depends.

With the most important element: what are you comparing to? When you compare a state-of-the-art digital press to an old offset press, the crossover will be very high. But if you have a superefficient offset press with an equally efficient workflow and orders that are a perfect fit for job ganging, the number might be very different…

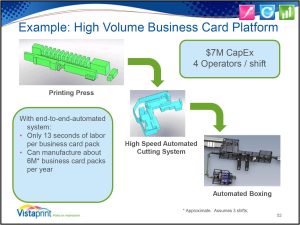

A concrete example to show this: a long time ago, when Vistaprint was gaining market share rapidly, especially in ‘small’ jobs, multiple small printers specializing in that kind of work complained to me, stating that Vistaprint was selling print products with losses. “I did the math: they can’t produce business cards at that price!” Well, these printers did the math, but based on THEIR equipment and THEIR workflow… And doing it that way, it would indeed be with a loss.

But Vistaprint was and is a high-tech company. Even in the early 2000s, they had a hugely automated workflow. The first moment a person touched a job was when the press operator took the exposed and developed plates out of the CTP system. Everything before that point was fully automated.

The presses were highly standardized, only CMYK, meaning: limited change over time and a limited amount of setup waste. And even the finishing was highly automated: Vistaprint had only one size of business cards, which allowed them to have a completely automated, unique cutting solution. Which made it very cost-effective for them to produce the print they offered. And Vistaprint was and is profitable, except for a few fiscal years.

BTW: do you know what their average order size is? In 2005 that was less than 30 US$… Which rose to around 44 US$ in 2015 (the latest number I found).

Job change sheetfed offset press: 2 min, 13 seconds

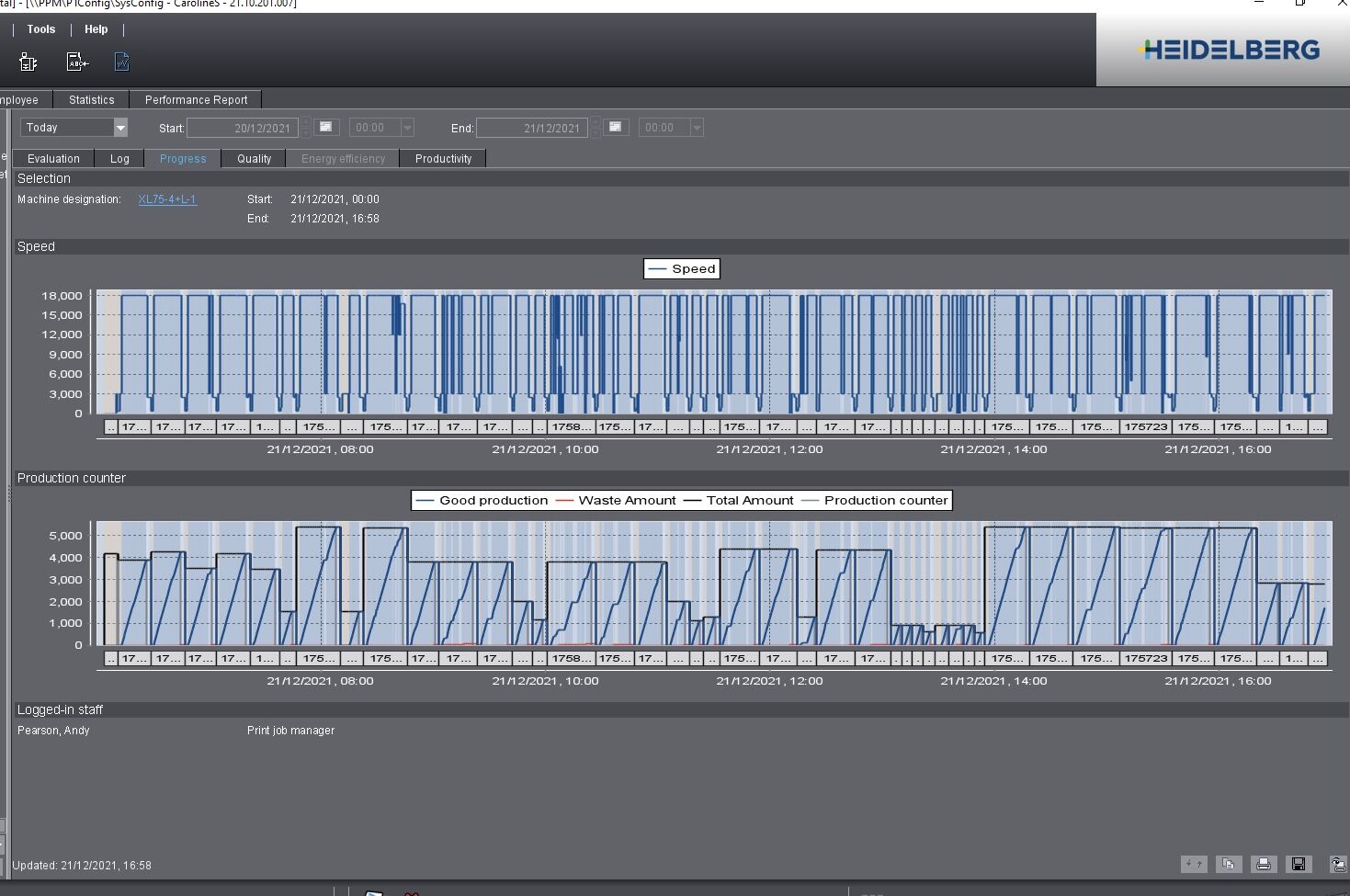

The key factor in the equation is the makeready of offset presses. When you want to print a new job, you need to place the new plates on the press, adjust some settings if you change substrate type or size, and ‘get up to color’. A significant cost. That’s what Landa Nano showed in the slide below (the white area is setup), during a webinar at the end of last year (December 2021).

To get a better view on makeready times for offset printing presses, I did a brief search. One of the first results I got is from an old thread on PrintPlanet.com, from the end of 2008/early 2009. Several people responded to the question about the average makeready on a four color sheetfed offset press. Several were around 30 minutes, some had makeready times between 10 and 20 minutes.

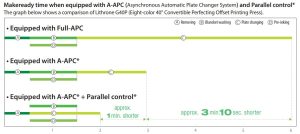

But this has changed: I remember several demos at drupa shows, with superfast job changes on sheetfed offset presses… Searching a bit longer, I found this video from Komori, from drupa 2016. Total time in between 2 jobs on their Lithrone GX40RP? Two minutes and 13 seconds… Which makes a big difference when talking about short runs and the crossover between offset and digital. Please note that in the Komori demo, both jobs were printed on the same paper (both type and size), so a job change only involved changing the plates. If the substrate needs to be changed, it’s a few minutes longer.

This Komori brochure from 2016 shows the advancements in makeready time.

The same brochure also mentions the number of setup sheets needed: less than 20.

Guess what Simian installed in 2016: a Komori Lithrone.

BTW: on this Komori web offset press, a full job change is less than 7 minutes…

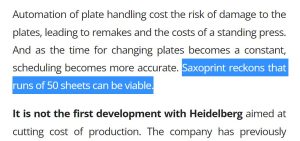

And then there is this article in Print Business, just two weeks ago, about the beta testing of a new automatic plate changing on a Heidelberg Speedmaster XL106. With this as a conclusion: “Saxoprint reckons that runs of 50 sheets can be viable.” Yes, 50 sheets! I’m not sure which digital presses they have, but I do know they were the first in the world to have a HP Indigo 100K installed.

Added 5/9/2022: Inkish.tv just published an interesting article on Saxoprint! Check it out! And here is the video.

For those mainly looking at digital, never forget: ‘old’ technologies fight back.

Why is this important?

The correct answer to the magical crossover is indeed: it depends…

Many factors influence the calculation. Plus: it’s also a business decision when to go for one or the other. And dear printer, that calculation: it’s something YOU have to make. And you HAVE to make that. And you have to do that BEFORE you sign any order, or even a letter of intent for a new investment. And you should not only compare that new digital equipment to your current press. No, you must compare that new digital press to a new offset press. That could make a huge difference.

You should not just rely on the marketing material from a vendor, not even a graph from a consultant, claiming it is x, y, or z. Relying on fancy graphs and bold claims could become very expensive. If you made your investment in digital based on a 5000 sheets crossover, you might be in for a big surprise…

PS: if you read this article because you are interested in Landa Nano, here are some other articles:

Failing nozzles in inkjet: what is acceptable? (16/08/2022)

The Landa Promise: source material (12/06/2022)

The Landa Promise: Eddy Hagen & Morten B. Reitoft (inkish.tv, 11/06/2022)

The Landa S10P World Record: a closer look at the numbers… (06/04/2022)

Landa Nano Print Quality IRL: inkjet vs inkjet (21/11/2020)

Landa Nano Print Quality IRL: I’m not impressed (15/10/2020)

Drupa 2020: Landa Digital Printing (26/01/2020)

UPDATE 02/09/2022: after having read my article, you might also want to read this article by Morten B. Reitoft (you know, from inkish.tv). Although he enters the discussion from an entirely different angle, we both come to the samen conclusion: printers should do their homework, themselves. They should not rely on what others claim. They should look at their orders, where they want to go in the future and based on that, do a calculation and make a decision…

Indeed. There is a lot of factors that affect this. The preset and inline measurement system of the press is a big factor when it comes t o make-ready times. Another factor is in which line of business you are. For instance if you are a popular top notch packaging printer, printing not only CMYK but perhaps CMYKOGV or fancy pancy Metallics and Neon spot colours each day, you can usually afford to take your time in make-ready and throw out 7-800 sheets pr. make-ready for a run of hundreds of thousands or even millions of full sheets, while if you are a medium sized commercial printer doing smaller runs of a few thousand each day, you really need to do to do the math, standardize your workflow to ISO standards and think about minimizing your make-ready time and virgin sheets going to waste with a good preset and closed-loop system. As much as I like to argue, Deborah is right. It depends.

Thanks Ingi!

Of course it depends. But with a factor 100 between the claims from Landa Nano and Saxoprint, one of them is very wrong. One of them is not comparing apples to apples. And that’s my point: you should never compare the latest, fully automated generation with a non-automated press from a decade or more ago. And that’s probably what Landa Nano has been doing. They are using very old numbers for offset.

Online printers, who need a standardized and automated workflow to be competitive in those short runs, show that offset can be competitive even for a few hundred sheets.

Saxoprint has recent digital equipment, they have to earn money with print, not with selling machines/consumables. I trust their calculation, although maybe a bit optimistic, more than the one from Landa Nano (who wants to sell machines/consumables). The one from Landa Nano is fantasy if you ask me.

The difference is interesting and the fact is that a big online printer who has access to both digital and offset presses, with customers who typically would be happy if their job was printed on a desktop office printer, have very little reason to lie. They don’t care if you pick analog offset or digital printing as long as you buy from them.

Ingi, I would not make such statements about customers off online printers… This just isn’t true (at least not anymore). The online printers that are still around, have invested heavily in standardisation and automation, they have good quality control in place. Just look at the first update I placed at this article: https://www.insights4print.ceo/2020/10/landa-nano-print-quality-irl-im-not-impressed/#Updates Someone else made the same claim as you just did. What I show in the update is my business card as an amateur photographer. This is a rather challenging job, registration must be perfect. And it was. And that for 25,25 euro, at an online printer.

Online printers are about speed, price, in some cases even customer service (yes, they do have that). Not about quality.

One advice: try it yourself! Order some prints from online printers.

I am not saying the quality of online printers isn’t good. I am saying I doubt that there are many customers that are overly concerned about whether the job is printed in offset or a digital press.

Unfortunately I strongly suspect most customers that buy directly from online printers, rather than leaving the choice of printer to an ad agency are simply not fuzzy when it comes to quality, accuracy of colour etc. – unfortunately.

Too many that DO have an ad agency employed don’t seem to be too fuzzy either, – which is especially sad for me.

Great article with interesting facts. Are these Saxoprint facts based on a Heidelberg Speedmaster with the Cut Star roll feeder? That means a large number of runs on the same stock, I assume. Saxoprint is very positive on the use of Cut Star technology and even upgraded an older press with Cut Star to increase the efficiency.

Thx Henk!

I’m not sure if the numbers of Saxoprint are based on the CutStar roll feeder. This is what the article says about the CutStar: “The company has previously installed an eight-unit perfecting Speedmaster XL162, together with a CutStar reel sheeter. That press model is no longer supplied by Heidelberg.” So, I assume the new one, on which I believe the 50 sheets crossover is based, doesn’t have that option anymore.

But I’m sure the crossover is based on jobs printed on the same stock. I should also note: I have beend told that changes in substrate also take adjustments, and therefore time, on the Landa Nano press. It’s not like in other digital presses where you have different bins with different substrates.

Thanks for the very interesting discussion with facts and figures. I’d like to add two ingredients to the mix: investment cost and press size. Certainly it must be taken into TCO (Total Cost of Ownership) calculations but, as a pure number, will shift printer decision at the beginning. Some presses, digital or analog, simply cost too much for the average sized printer shop, they can’t get a proper financing. Therefore a digital solution, Landa excluded for the super high costs, remains as a viable solution. Some comments about size. Offset presses are today really good but they remain big in occupation area. A digital solution (let’s speak about HP or similar products) is definitively smaller.

Thanks Marco!

And I agree. Every printer should make his own calculations and buy the press that best fits his print work, his print shop…

Hi Eddy

Good piece. Your finding echo what I see in the real printing world. And, of course, it depends…..

Thanks Paul! 🙂

Antony Thirlby is owner of Venn and has a printing company and a digital press company (helloJDP/John Dolin Printing/Culverlands Press) in the UK. He owns Heidelberg Speedmaster presses and a HP digital machine. With a great track record on efficiëncy. See his posts on LinkedIn and his contributions for both HP and Heidelberg. I think, he is the ultimate printer with both technologies and Anthony is a experienced consultant and workflow/optimization specialist. Ask him for the numbers he uses.

Indeed Henk!

I shared one of his posts in the past, your comment reminds me that I should also share it here: https://www.linkedin.com/posts/activity-6944912049315454977-zX0l?utm_source=linkedin_share&utm_medium=member_desktop_web

This is BTW some statistics he shared on LinkedIn: