With the vacation approaching, here’s something to think about: CSRD, the ‘corporate sustainability reporting directive’ and how this will affect print, and more specifically: press checks and tiny tolerances… Your first response might be that this only applies to large corporations, but you might want to look twice: these companies will want your data, even if you are a small company… Let’s dive into this important legislation!

CONTENTS: The letter soup | Scopes 1, 2, 3 (you’re it!) | A look at current sustainability reporting | Making your dossier | Why is this important?

In my daytime job, CSRD is beginning to make its entrance: transport companies are getting questions from, e.g., FMCG companies about their CO2 emissions. And from a conceptual point of view, transportation and printing are similar: they provide services/products to other companies, in many cases large companies.

The letter soup

When talking about CSRD, you can be confronted with lots of abbreviations. If you don’t like abbreviations, you might want to skip this part.

First, there is the CSRD: corporate sustainability reporting directive. This is an EU legislation. The next step is ESRS: European Sustainability Reporting Standards. These are the standards and procedures that practically implement CSRD, the ‘framework’ for reporting. The ESRS standards will have both ‘general’ requirements (sector agnostic) and sector-specific requirements. ‘Food and beverages’ is one of these sectors, and with that, packaging comes into sight.

EFRAG develops these ESRS standards: European Financial Reporting Advisory Group. And here you can see a link with financial reporting: SFRD, Sustainable Finance Disclosure Regulation, a regulation that became effective in 2021. This one focuses on asset managers, financial advisers, and insurance providers in the European Union. Next to that SFRD, there is also the NFRD: Non-Financial Reporting Directive, which applies to European listed and large public-interest companies. In short, you could see CSRD and the practical implementation of ESRS as successors to the SFRD and NFRD.

There are still other standards, like GRI (Global Reporting Initiative), SASB (Sustainability Accounting Standards Board), and ISSB (International Sustainability Standards Board). More on those and how they relate to CSRD in this article.

And now I’ll stop with that letter soup… It’s making me nervous.

When? Who?

CSRD applies to large and listed companies (except for listed micro-companies) based in the EU. But it also applies to third-country companies based outside the EU but with subsidiaries and branches in the EU.

There are 4 stages:

- 1 January 2025: companies that are already reporting NFRD must report their first set of sustainability reports on the fiscal year 2024

- 1 January 2026: other large companies (so those who do not report NFRD) need to report on the fiscal year 2025

- 1 January 2027: listed SMEs need to start reporting on the fiscal year 2026, there is a possible ‘opt-out’ until 2029

- 1 January 2029: non-EU companies listed in EU markets with subsidiarity in the EU and working in the EU and >250 employees, plus either at least 40 million euro turnover or balance sheet total of at least 20 million euro, need to report on the fiscal year 2028.

Scopes 1, 2, 3 (you’re it!)

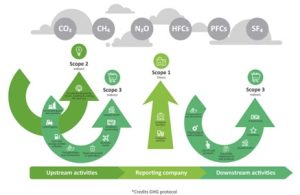

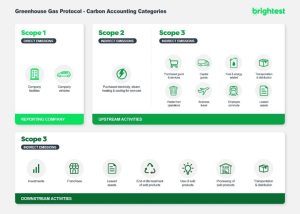

An essential concept in sustainability is the three different scopes of your reporting. In short: Scope 1 is everything you do yourself, your direct emissions. Scope 2 is the energy you buy, which is indirect emissions. And Scope 3 is the tricky one: the emissions of your supply chain, both upstream and downstream. And that’s where printing becomes relevant…

When a large FMCG group, like P&G, wants to report on Scope 3, it will ask its suppliers to give them information for that reporting. And that includes their packaging printers, converters…

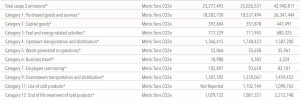

Scope 3 is, BTW, mandatory in the European CSRD… So, to comply, P&G should (will) ask their printers, no matter the size, to provide information for this CSRD reporting. And in case you might think I’m making this up, this is a paragraph in their latest report, on the 2020 Goal Measurement Systems: “Paper Packaging – Data for calculating progress versus our paper packaging goal was self-reported by our suppliers. The data collected this year covered materials procured directly by the company as well as contractor manufacturers and covered more than 98% of our global spend.” (bold is mine)

A look at current sustainability reporting

Many or most ‘public’ companies already publish an ESG report (environmental, social, governance). I checked a few to get an idea of what some well-known FMCG companies, which are large print buyers, are reporting on. Here are the links to their reports and some key elements they say about packaging and packaging waste…

Unilever: “100% reusable, recyclable or compostable plastic packaging by 2025” (more)

Mondelez: “Make 100% packaging designed to be recyclable by 2025.” (more)

PepsiCo: “In early 2022, PepsiCo Europe set a new ambition to use 100% recycled or renewable plastic in all crisp and chip packets by 2030, which is expected to reduce GHG emissions from film packaging for food by up to 40%.” (more)

P&G: “100% of our plants are now zero manufacturing waste to landfill.” (more)

Coca-Cola: “In 2023, we are building our capabilities in life cycle assessment (LCA) to further drive synergies between our work on packaging and climate.”

“As of 2022, we reduced our emissions across Scopes 1, 2 and 3 by 7%, making progress toward our science-based reduction target of 25% by 2030 against a 2015 baseline. Our ambition is to achieve net zero emissions by 2050.” (more)

KraftHeinz: “Aim to make 100% recyclable, reusable or compostable packaging by 2025.”

“Our comprehensive approach to packaging seeks to meet extensive packaging regulations, aims to cut waste, (…).” (more)

With all the examples above, it’s clear that these companies take ESG reporting seriously AND that they have added Scope 3, meaning: they are looking at their partners, e.g., the printers/converters they work with.

And that’s where the discrepancy between the company goal to reduce emissions, also in Scope 3, and that overcritical print buyer who is unhappy with a decent print job and demands ever smaller tolerances! Making it harder to get it ‘right’ (in his eyes), resulting in more setup waste, maybe even rejected jobs… Which means: a lot of unnecessary waste…

I would love to see the discussion between the ESG division and such an overcritical print buyer… that’s what you, dear printer, should use as an argument: the ESG goals of your customers.

Making your dossier

If you want to start the dialogue with an overcritical print buyer or brand owner, one with unreasonable demands, resulting in more waste, here are some facts you can share.

- There are no studies showing that a color difference would lead to a loss in turnover in real life. The claim that color increases brand recognition by up to 80%, is from studies on newspaper ads: when comparing color versus black/white advertising, color did increase brand recognition. But this is NOT on small color differences. More on that in this article.

- And this quote: “People make up their minds within 90 seconds of their initial interactions with either people or products. About 62-90 percent of the assessment is based on colors alone.” I could not find any sources for that. But the context it was first used in, was apparel, not FMCG. And ‘color’ in that case meant ‘color category’ (red or green), not between, e.g., Pantone 185 C and Pantone 186 C.

- The interaction time of a consumer with a package is extremely short, as studies with eye-tracking have shown. On average: less than a second. Coca-Cola? One-tenth of a second. You can’t detect small color differences in that time frame. This article has links to these studies.

- Another factor why it’s difficult to detect small color differences between individual packages: the world isn’t flat, it’s 3D. And our brain corrects for this kind of situation, our brain even plays tricks on us… Our brain will always tell that the red is Coca-Cola red, even if it’s several dE00 off.

- Our color memory is also flawed. Even when you are shown a reference and you immediately need to pick that color from a series of colors, there is already a distortion, a shift towards the ‘middle’ of that color category.

- A test with the most iconic brand color, Coca-Cola red, where participants were shown 6 variations of red, all brand colors of famous brands, showed that the most picked color wasn’t the right one. It was 4,3 dE00 apart from the right one. Even the one that was 9,2 dE00 off, was the second most picked choice, on a tie with the right one. https://www.insights4print.ceo/2022/07/399-iconic-color-memory-tests-some-interesting-conclusions/

- And a survey of over 100 consumers showed they are rather tolerant towards color differences. Promotions are much more dangerous for ‘brand loyalty’ than color differences.

- Last but not least: our mindset changes when doing a visual press check. We want to find color differences. Making us see differences where there are none, as was shown in this study. About one in three print professionals claimed to see a color difference between two identical copies… It’s psychology. Also when doing visual press checks.

- The idea that an exact reproduction of a brand color is necessary lives only in the printing industry echo room. And in that quest, some important facts are forgotten: defining brand colors by a Pantone number is flawed (that’s why we started Project BBCG). Pantone color guides have tolerances, their ‘aim’ is 2 dE00. As a consequence, since dE doesn’t show direction: 2 copies can be 4 dE00 apart and still fall within that 2 dE00 aim… Also, spectrophotometers have tolerances. All of this has been discussed in the ‘Chain of Tool Tolerances’.

- And a last one, a fact that has not been studies a lot: the color of ink changes during drying… I’ve seen these kind of changes with offset ink in the past, if I recall correctly even up to 2 dE00… Here is the only public study I could find on this phenomenon, which is called ‘dryback’.

Why is this important?

ESG reporting is becoming significant for large companies, especially FMCG. They want to have a positive sustainability image towards their customers, consumers. That’s why they have a central division for ESG, which sets up concrete action plans. And printers/converters will be required to follow, since they are an important part of Scope 3. But there is, or can be, a discrepancy between the demands of the ESG department and the people doing the press checks for that company… The first wants to cut emissions, and the second may demand color tolerances below those included in international standards, regardless of whether this generates extra waste.

Oh, one last thing: in case you are still not convinced this is relevant to printers/converters, I checked with my friend dr. Kai Lankinen. Several companies have already approached him to assist them with this. Both packaging printing companies and print buyers…

Hi Eddy

Dry back is an issue where there is no assisted drying on a press. Most of the process control software’s such as Bodoni PressSIGN and MellowColour PrintSpec have methods in their software to deal with this issue.

Thx for the feedback Paul!