As I showed in the previous article, ECG printing (expanded or extended color gamut) is feasible from a technological point of view. Even more: it has lots of benefits. And guess what: most brand owners want it! They even want it for a large part of their print jobs. That’s the main conclusion of the survey my friend dr. Kai Lankinen did with international, and global brand owners. And, dear printers and prepress houses, many look at YOU to propose ECG to them!

CONTENTS: The Survey | Why is this important?

During the last LabelExpo, in September in Brussels, special attention was paid to ECG printing. Dr. Kai Lankinen organized special ECG tours and presentations on how ECG can be used in packaging and labels printing. In preparation for these presentations, he surveyed several brand owners. He has already shared the main results on LinkedIn, but I’m happy to publish his updated results here on my blog with his permission. The results I show here are an update of the results previously published on LinkedIn as the total number went from six to seven. This might seem low, but Kai said it’s statistically enough and relevant. From my perspective, it offers some interesting food for thought!

The survey had seven questions, which I’ll address one by one.

1. Are you familiar with the Expanded Color Gamut printing (ECG)?

This is a simple one: all were (more or less) familiar with ECG.

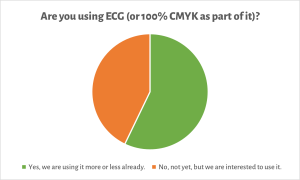

2. Are you using ECG (or 100% CMYK as part of it)?

It’s interesting to see that the majority is already using ECG or CMYK, but it also shows there is still a lot of potential…

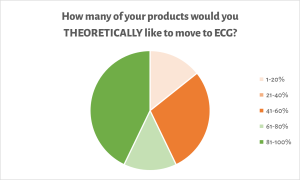

3. According to the Dr. Lankinen Ph.D. study (Tampere University, 2021): “With ECG printing the CO2 equivalent is reduced by 34% to 51% compared to SPOT color printing”. – How many of your products would you THEORETICALLY like to move to ECG?

This again shows the potential for ECG! Non selected the option ’0%’. A substantial portion of products could be moved to ECG.

Please also notice the way Kai asked this question: he made the link to the reduction of CO2. And that could be an interesting ‘sales pitch’. All the big brands have ESG (environmental, social, governance) reports, with bold claims that they will reduce the Scope 3 emissions, even in the short term. And guess what: package printing is included in Scope 3, as I already showed in this article!

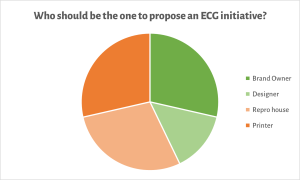

4. Who should be the one to propose an ECG initiative?

And talking about that sales pitch: most brand owners are looking at you, dear printers and prepress houses! You should convince brand owners! This was also feedback from one of the brand owners: “designers should be educated on this.”

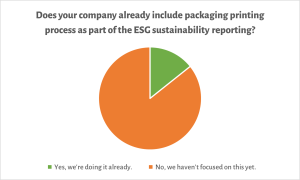

5. Does your company already include packaging printing process as part of the ESG sustainability reporting?

This is again interesting: when I looked at several ESG reports from big brand owners, they all made these bold claims about CO2 or GHG (greenhouse gasses) reduction, by 2030. However, it seems the ESG department’s message has not yet reached the print buyers in those companies. And here is some homework for the sales reps, the management of packaging printing companies, and prepress houses: check the ESG reports from your customers! These are often found on their website, since they consider this nice publicity for their environmental efforts. But these claims need to be translated into action, it’s not only the packaging material itself, but also the printing / converting process influencing on GHG. As Kai showed in his PhD thesis, moving from spot colors to ECG can positively affect GHG emission reduction.

The following two questions were open questions:

6: What are the biggest obstacles, if any, in implementing an ECG project into the FMCG business?

7: What feedback, if any, would you like to tell to printers additionally?

Standardization is one of the obstacles mentioned. And this was also important feedback: “Proactively bring forward design and manufacturing opportunities to Brand Owners. The printer is at the crossroads of Brand Owner, Designer, Workflow and Production.” Dear packaging and label printers: it’s going to be YOU who has to sell ECG to brand owners. If you wonder why, what’s in it for you: standardization of production and, by that, a more stable, predictable, and cheaper production. Wouldn’t that be interesting? Also, for prepress houses, this might be economically interesting: moving to ECG might involve more work on their side than spot colors, leading to an increase in turnover.

With ECG there are no longer restrictions on number of colors printed (e.g. 8), because with ECG’s digital color mixing printer can simulate, for example, 15 spot colors on one pack. And the best part is, as per Kai, ECG typically reduces the total number of printing plates by about 10%. Check out the real-life designs and think about the potential benefits it offers to the entire production chain, also including the ESG reporting.

Why is this important?

ECG (expanded / extended gamut printing) is a reality. It’s feasible, both technically and economically. And there is a lot of potential to move the packaging, the labels of FMCG products to ECG. But we need to get everyone involved to get it widely adopted and used where it makes sense. ESG might become the trigger to convince those brand owners…

PS (05/11/2023): I’ve updated the article a little bit, mentioning several times that ECG printing is about packaging and labels. For commercial printing, the cases are more limited.

Eddy – happy to have had such an influence on your personal branding. I hope you will continue to embrace your provocateur status and hold people accountable for their claims – and the clarity of those claims. I will check my list of Landa installs and if I have any that you missed.

Thanks Elizabeth! 🙂

ECG is feasible from a technological point of view – and of course brand owners and designers like the idea of being able to print all the colours in the world and even their good old Pantone colours, at no added cost v.s. printing in CMYK.

The obstacles are however:

1) Designers / Agencies usually don’t have access to ECG printshops – simply because most Printshops focus on CMYK. That means that their fleet of printing presses can only handle CMYK printing – 4 colours, because each press only has 4 printing units.

2) ECG is not supported by Adobe. In order for designers to start using ECG, they need to be able to select the ECG icc output profile in their Adobe or Affinity app – and they need access to ECG colour palettes from within their Adobe or Affinity app.

3) For some reason ECG is only adapted for Coated, Premium paper. In order for real success, icc profiles must be built also for uncoated substrates – basically the same papertypes outlined in the ISO 12647-2-2013 standard. Until then ECG will only be a novelty, – not for mainstream use by brands – in my opinion.

Ingi, I think you are missing an important point: when talking about ECG, we’re talking about packaging printing, not about commercial printing. And for packaging printers presses with more than 4 colors are the standard, not the exception. Flexo presses often have more than 7 colors, the number you need for ECG. This Bobst flexo press e.g. has standard 10+ colors. These two Heidelberg offset presses have 19 and 20 units… (ok, one of them is for double-sided packaging, but that’s even 10 colors on both sides)

Plus: prepress for packaging is also very specialized, these are dedicated shops (repro houses), which have the tools to deal with ECG.